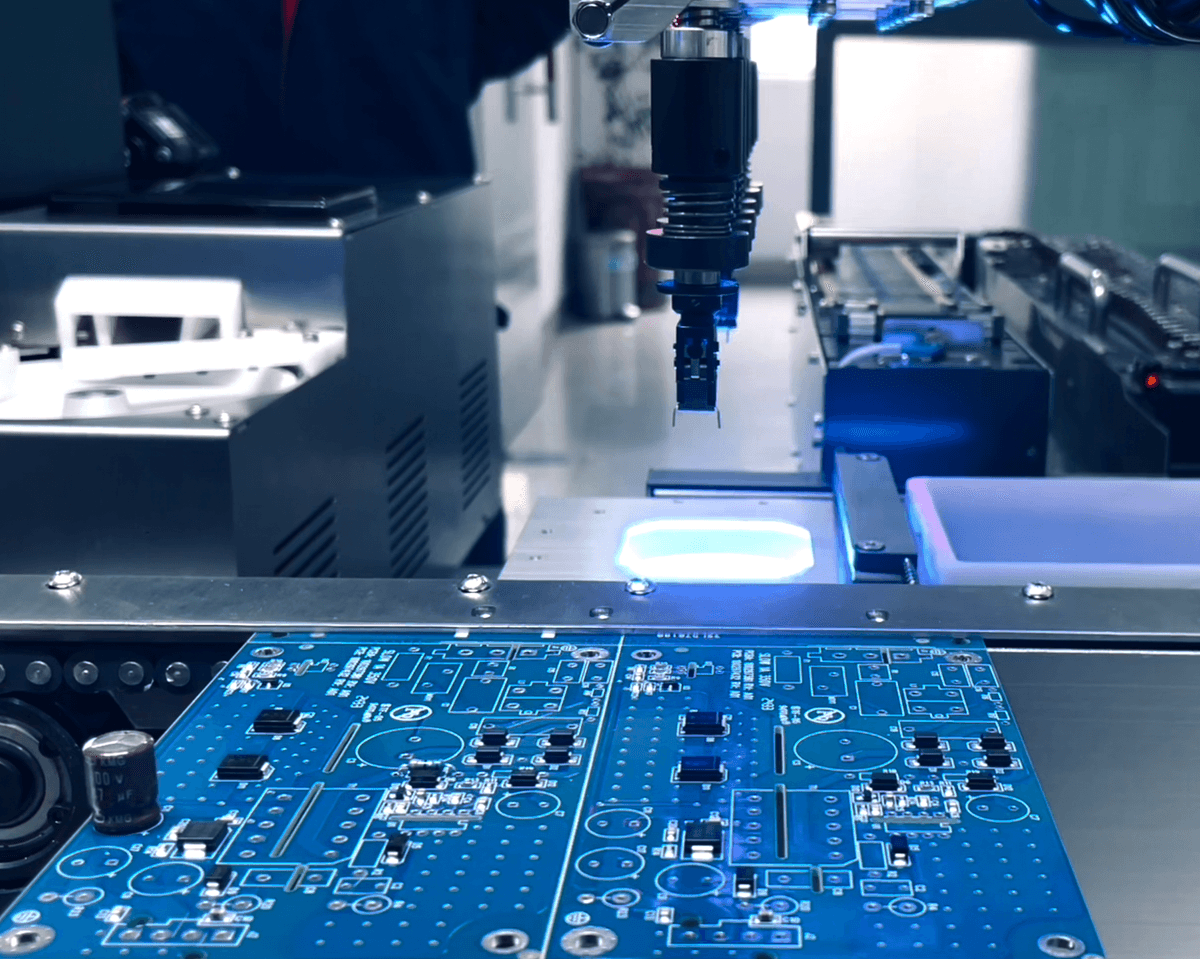

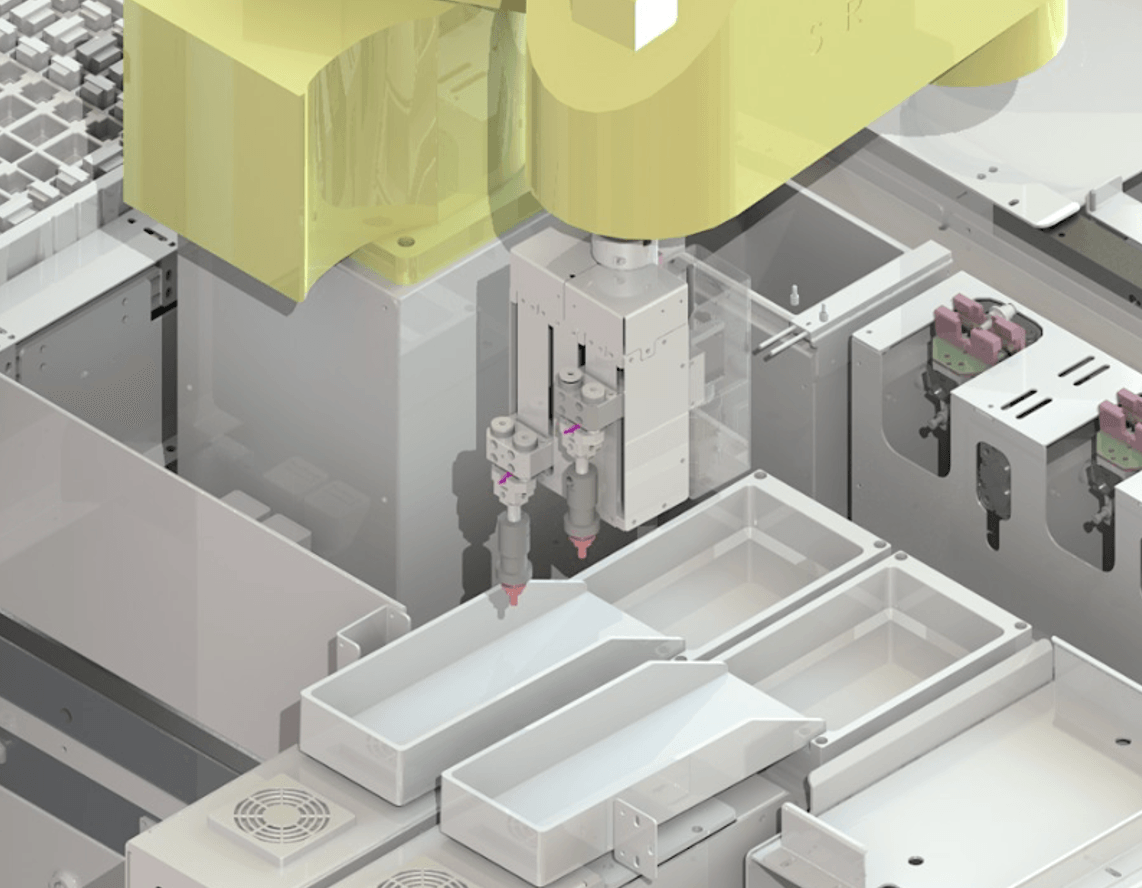

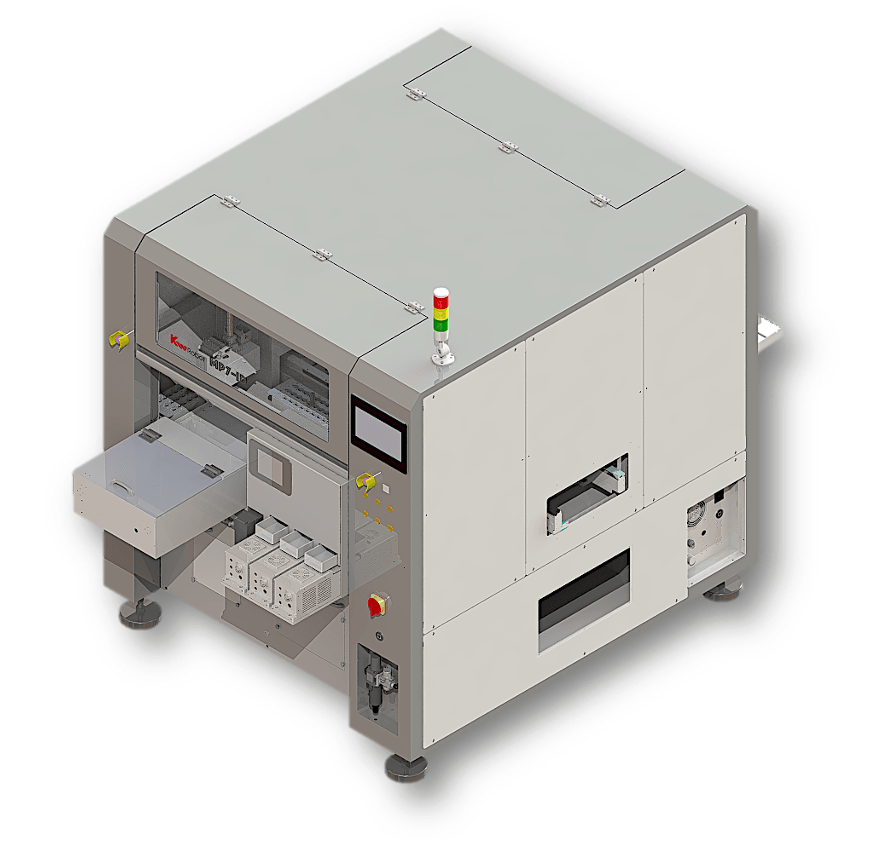

PCB heteromorphic plug-in machine MP7-ID

MP7-ID Join your production team. Accelerate your productivityFANUC ROBOT Precise and fast plug-ins

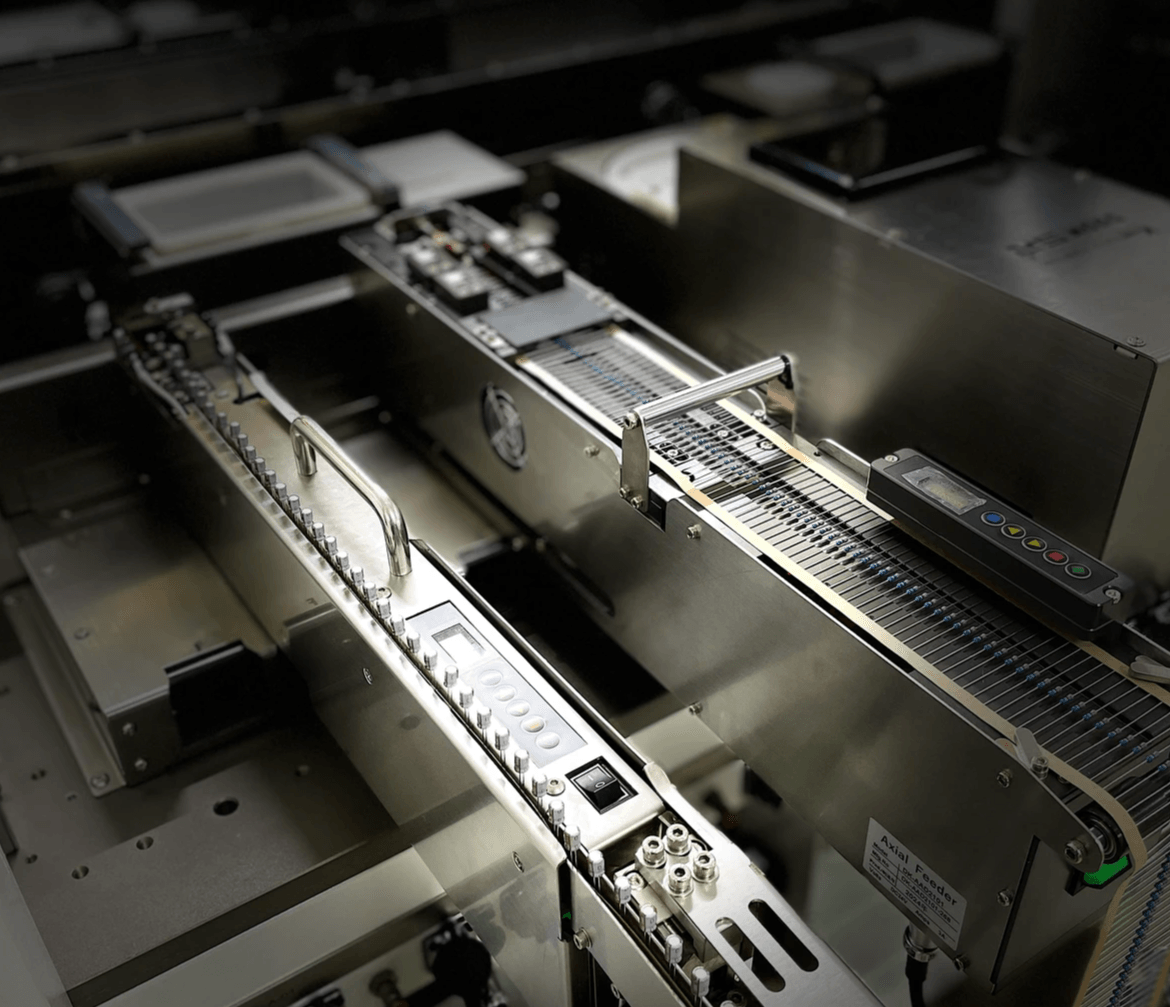

Intelligent and standardized all-round feeder

Flexible parts. Vertical sidebands. Horizontal sidebands. IC tubular. Tray packing. Mixed trays. Label feeder.

High coverage component insertion

Achieve more than 98% of the plug-ins with high coverage of your product components, and automatically change production lines to increase production capacityFANUC ROBOT's precise and high-speed plug-ins have high obstacle avoidance capabilities, and perfectly present the production methods you need.

Flexible feeder for bulk materials

Using state-of-the-art technology, our system integration services can significantly improve production efficiency, reduce labor costs, and shorten production cycles. This will give businesses a greater competitive advantage.

Bulk materials are directly fed, reducing material costs, visual automatic discrimination and screening of materials, high versatility, and a variety of materials are used

A wide range of feeder feeder options

We provide comprehensive technical support services, including installation, commissioning and follow-up maintenance, to ensure that users have no worries during use. A dedicated team is always available to answer your questions.

Mixer feeder

Provide a set of feeders for different materials at the same time, reduce costs, reduce equipment space, and increase production flexibility

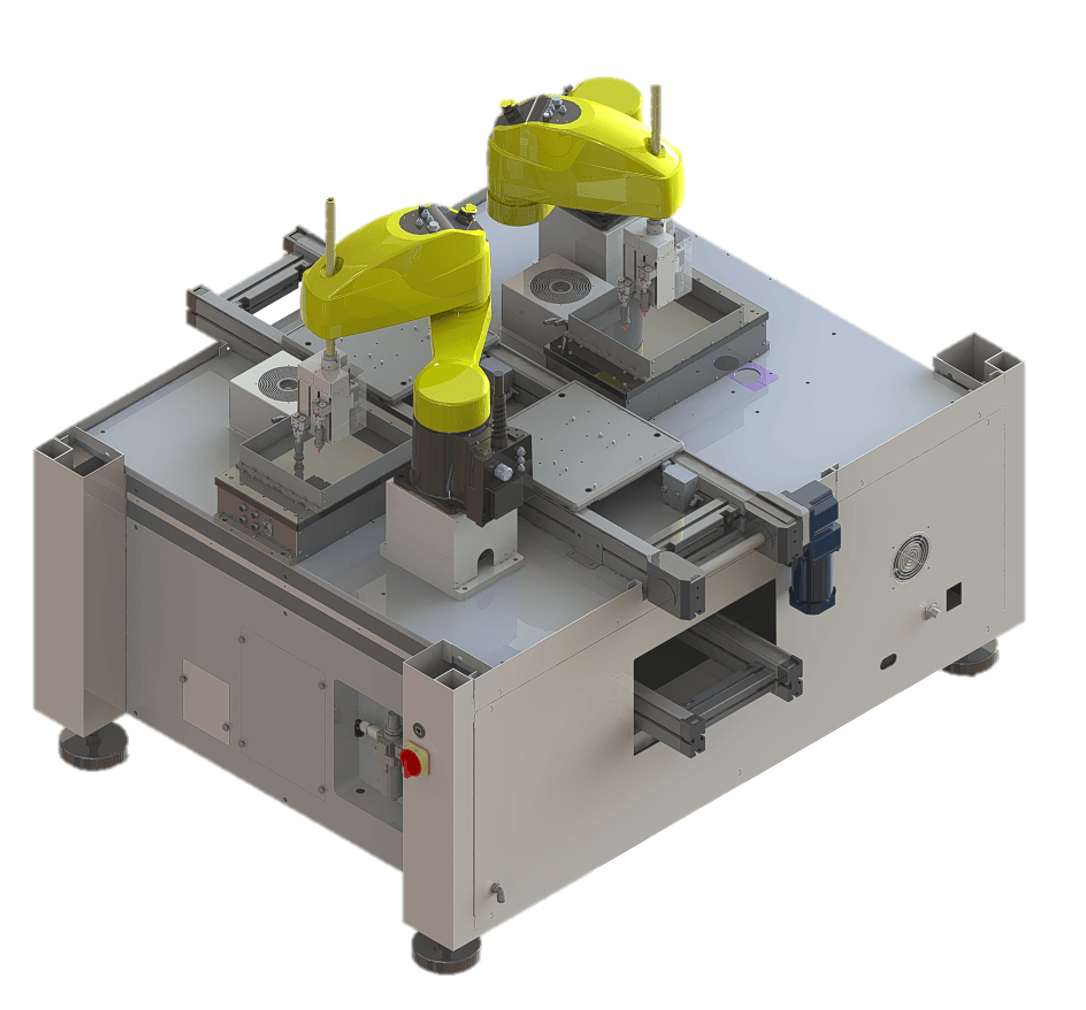

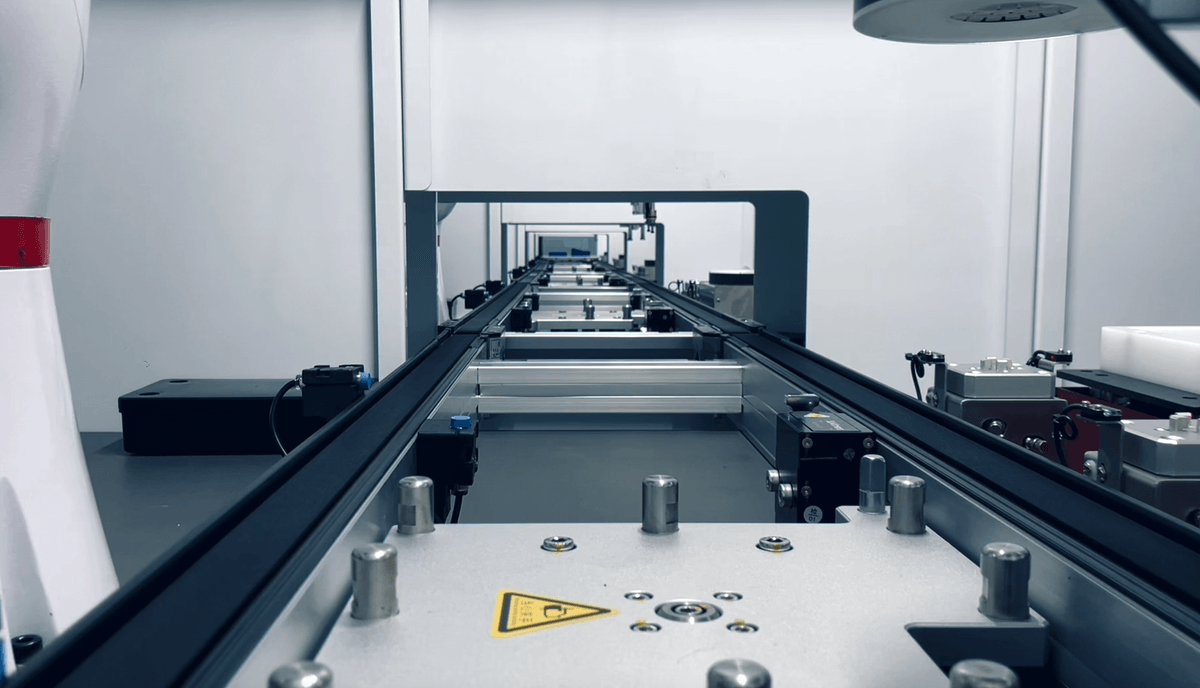

ARA - Robot Standard Automatic Assembly Line

Fast automatic line change. Applicable to various product assembly. More flexible than flexible!

Using this production system can greatly improve production efficiency and stability and meet the production needs of all your products.

Standardized design. Flexible technology

Achieve full process automation and human-machine collaboration goals

The automation solutions we provide can achieve full automation of the production process through standardized design, significantly improving production efficiency and reducing labor costs. Whether it is an assembly line or special equipment, it is the most suitable automation system. Automatic and fast line change helps you complete the production of small quantities of diversified products. The AI system automatically optimizes production efficiency. It is a simple and practical best solution.

Flexible feeder. The most powerful commonality

Irregular loose parts can be easily loaded and are suitable for various materials

If you want strong commonality, you must adopt a flexible solution. No matter what kind of loose materials, you can use visual recognition and flexible feeders to complete the automatic feeding process. Different materials can share the same set of feeders, and you don’t have to worry about installation positions and material jams. Flexible feeders enhance the mobility and efficiency of automated production lines. Through this innovative technology, companies can adjust production needs at any time, flexibly respond to market changes, further enhance overall competitiveness, and achieve higher production goals.

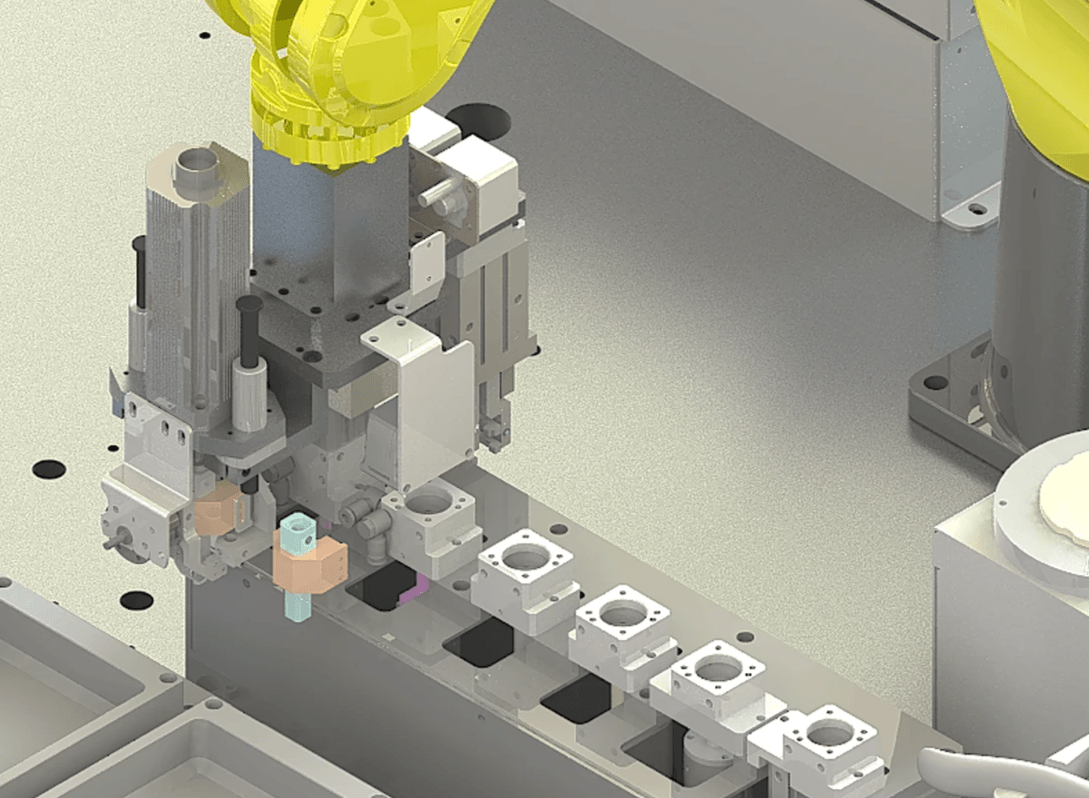

Standard ACT tool changing system

Robots are smarter in automatically selecting tools for work

The complex production processes of different products require a complete set of tool systems that are integrated and applied in the ARA system to perfectly match the processes required for various production processes to ensure the accuracy and efficiency of production, and realize intelligent production models to meet the ever-changing market demands.

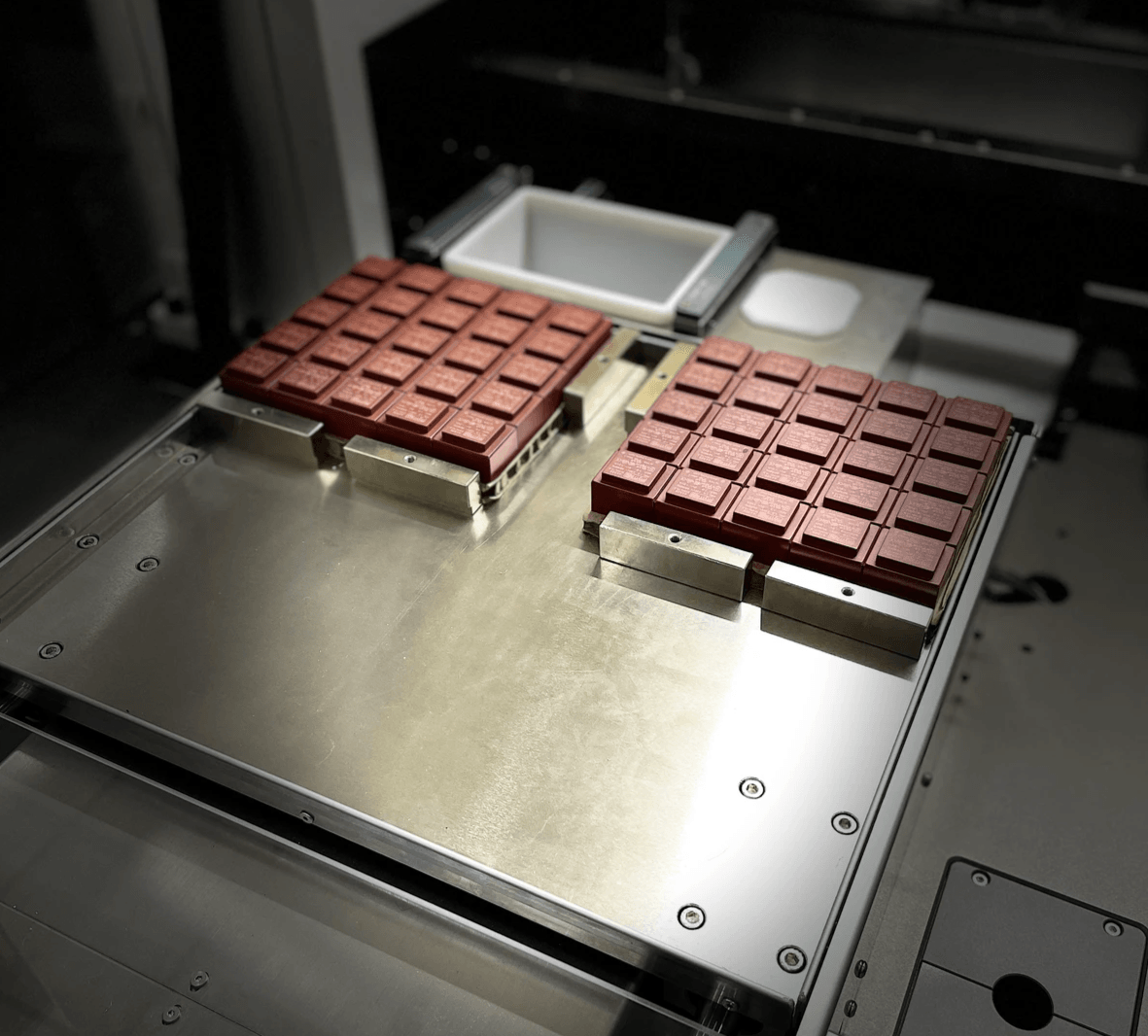

Mixing feeder for trays. Satisfy your design process

Key flexible layout reduces equipment cost investment

The materials can be mixed and fed together, which will greatly save the installation space inside your equipment. This is an innovative idea. When used with the KW automatic feeder, it can show a more intelligent production system. Feeding will no longer be a problem for you. Through this efficient feeding method, you can focus on improving product quality and production efficiency, making your business operations smoother.

Flexible equipment layout. Highly flexible production

Add or reduce equipment to adjust freely according to the factory's order pattern

Standardized equipment and intelligent control systems perfectly match your company's order ecology. Whether the automatic production line is expanded or reduced, it can be freely arranged and adjusted according to your needs. The rapid change of automatic production line will become the key to your success. With our professional technology and support, you will be able to keep abreast of market trends, improve production flexibility and ensure that you maintain an advantage over the competition.

Beautiful equipment appearance. Add points to your business

The domineering and noble temperament shows the excellent brand image and unparalleled technical strength

The beautiful, technological and highly secure design makes your company's technical staff safer when operating, and VIPs can fully experience our expertise and innovation during their visits, thus enhancing the corporate image. This design not only improves the safety of the working environment, but also demonstrates our insistence on quality and details, allowing every user to feel the convenience and comfort brought by technology.

Welcome large-volume project strategy DRDM leasing cooperation to expand into a larger international market!

Successful practice cases, demonstrating our leading technologies and applications in the industry

Intelligent detection, seamless integration of production lines

1. Introduction With the rapid development of electronic products, the requirements for...March 26, 2025 · 成功案例With the increasingly lightweight and efficient electronic products, the process requirements of...March 19, 2025 · 成功案例With the rapid development of industrial automation and artificial intelligence (AI) technology,...March 12, 2025 · 成功案例Many companies have introduced automated equipment, robots, and AI intelligent systems in the...March 11, 2025 · 成功案例Under the trend of Industry 4.0, artificial intelligence (AI) vision technology has become an...March 5, 2025 · 成功案例Choosing the right automation equipment is crucial to improving production efficiency and...

About Us

Our Mission

We're Hiring!

信息

幫助文檔

品牌優勢

Contact us

We look forward to hearing from you!

+86-135-0984-9960

kinglee_kwrobot@163.com

Subscribe to Our Newsletter